BM series thin film evaporator

Quality first, attentive service

<strike id="o6mqs"></strike>

BM series thin film evaporator

Quality first, attentive service

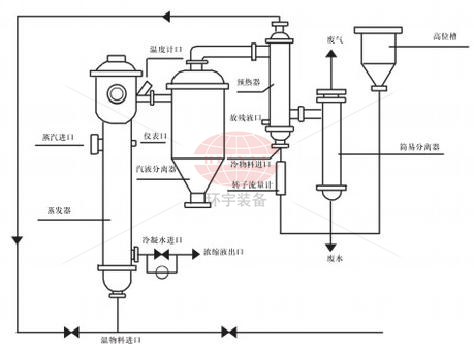

This thin film evaporator unit consists of three components: evaporator, vapor-liquid separator, and preheater, as well as a simple separator. The evaporator is a rising film tube heat exchanger.

This evaporator has the characteristics of high production capacity, high efficiency, and short material heating time, and is suitable for dilute solution concentration in industries such as pharmaceuticals, food, and chemicals. The parts in contact with the materials are made of stainless steel, which has good corrosion resistance, durability, and meets the requirements of pharmaceutical hygiene.

| Name/Specification | 2.2M² | 5.5M² | 8M² | 12M² | 16M² | 20M² | 30M² | 40M² | 60M² |

| Evaporation area(M²) | 2.2 | 5.5 | 8 | 12 | 2.2 | 20 | 30 | 40 | 60 |

| Preheating area(M²) | 1 | 2.17 | 4 | 6 | 1 | 10 | 15 | 20 | 30 |

| Steam working pressure (MPa) | 2.4 | 0.4 | 0.4 | 0.4 | 2.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Available steam degree (kPa) | 6 | 60 | 60 | 60 | 6 | 60 | 60 | 60 | 60 |

| Evaporation rate (kg/h) | 140 | 350 | 550 | 850 | 140 | 1500 | 2100 | 2800 | 4200 |

| Energy consumption (kg/h) | 155 | 385 | 605 | 935 | 155 | 1650 | 2310 | 3080 | 4620 |

| Medium | Shell side: Steam Pipeline: Medication | ||||||||

| Equipment weight (kg) | 300 | 520 | 750 | 1020 | 300 | 2300 | 2950 | 4500 | 5700 |

| Dimensions (mm) |

2000×850 ×3500 |

2300×800 ×3500 |

2700×950a ×4500 |

2000×850 ×3500 |

2900×950 ×5200 |

2800×1400 ×5300 |

3800×1800 ×6050 |

1200×1800 ×5050 |

5000×2000 ×5700 |