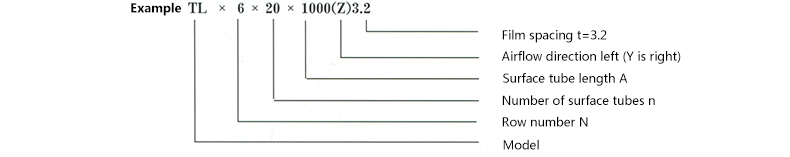

TL type surface cooler

Quality first, attentive service

<strike id="o6mqs"></strike>

TL type surface cooler

Quality first, attentive service

The TL type surface cooler is a copper tube through aluminum plate surface cooler, which adopts a mechanical expansion tube and a curved corrugated double flanged aluminum auxiliary plate structure. Mechanical expansion of the tube ensures tight contact between the copper tube and the aluminum foil, and the circular ripple can accelerate fluid turbulence, destroy the boundary layer, and improve the heat transfer coefficient. The structural type, combined with the reasonable design of waterway travel, pipe spacing, and sheet spacing, makes this surface cooler have the characteristics of good heat transfer performance, low air resistance, compact structure, and light weight.

|

Number of surface tubes n |

Effective high B |

Full height B1 |

Width C | c¹ | c² |

Pipe diameter a |

Effective manager A |

A2 | |||||||||

| 2 rows | 4 rows | 6 rows | 8 rows | 2 rows | 4 rows | 6 rows | 8 rows | 2 rows | 4 rows | 6 rows | 8 rows | ||||||

| 4 | 152 | 228 | 160 | 180 | 260 | 330 | 66 | 100 | 165 | 230 | 47 | 40 | 47.5 | 50 | 48×3.5 | 300-3000 | 178 |

| 6 | 228 | 304 | 160 | 180 | 260 | 330 | 66 | 100 | 165 | 230 | 47 | 40 | 47.5 | 50 | 48×3.5 | 300-3000 | 178 |

| 8 | 304 | 380 | 160 | 180 | 260 | 330 | 66 | 100 | 165 | 230 | 47 | 40 | 47.5 | 50 | 48×3.5 | 300-3000 | 178 |

| 10 | 380 | 456 | 160 | 180 | 260 | 330 | 66 | 100 | 165 | 230 | 47 | 40 | 47.5 | 50 | 48×3.5 | 300-3000 | 178 |

| 12 | 456 | 532 | 160 | 180 | 260 | 330 | 66 | 100 | 165 | 230 | 47 | 40 | 47.5 | 50 | 48×3.5 | 300-3000 | 178 |

| 14 | 532 | 608 | 160 | 180 | 260 | 330 | 90 | 100 | 165 | 230 | 35 | 40 | 47.5 | 50 | 60×4 | 300-3000 | 190 |

| 16 | 608 | 684 | 160 | 180 | 260 | 330 | 90 | 100 | 165 | 230 | 35 | 40 | 47.5 | 50 | 60×4 | 300-3000 | 190 |

| 18 | 684 | 760 | 160 | 180 | 260 | 330 | 90 | 100 | 165 | 230 | 35 | 40 | 47.5 | 50 | 60×4 | 300-3000 | 190 |

| 20 | 760 | 836 | 180 | 200 | 260 | 350 | 100 | 100 | 165 | 230 | 40 | 50 | 47.5 | 60 | 75×4 | 300-3000 | 205 |

| 22 | 836 | 912 | 180 | 200 | 260 | 350 | 100 | 100 | 165 | 230 | 40 | 50 | 47.5 | 60 | 75×4 | 300-3000 | 205 |

| 24 | 912 | 988 | 180 | 200 | 260 | 350 | 100 | 100 | 165 | 230 | 40 | 50 | 47.5 | 60 | 75×4 | 300-3000 | 205 |

| 26 | 988 | 1064 | 180 | 200 | 260 | 350 | 100 | 100 | 165 | 230 | 40 | 50 | 47.5 | 60 | 75×4 | 300-3000 | 205 |

| 28 | 1064 | 1140 | 180 | 200 | 260 | 350 | 100 | 100 | 165 | 230 | 40 | 50 | 47.5 | 60 | 75×4 | 300-3000 | 205 |

| 30 | 1140 | 1216 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 90×4.5 | 300-3000 | 220 |

| 32 | 1216 | 1292 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 90×4.5 | 300-3000 | 220 |

| 34 | 1292 | 1368 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 90×4.5 | 300-3000 | 220 |

| 36 | 1368 | 1444 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 90×4.5 | 300-3000 | 220 |

| 38 | 1444 | 1520 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 110×4.5 | 300-3000 | 240 |

| 40 | 1520 | 1596 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 110×4.5 | 300-3000 | 240 |

| 42 | 1596 | 1672 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 110×4.5 | 300-3000 | 240 |

| 44 | 1672 | 1748 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 110×4.5 | 300-3000 | 240 |

| 46 | 1748 | 1824 | 210 | 220 | 280 | 350 | 115 | 115 | 165 | 230 | 47.5 | 52.5 | 57.5 | 60 | 110×4.5 | 300-3000 | 240 |