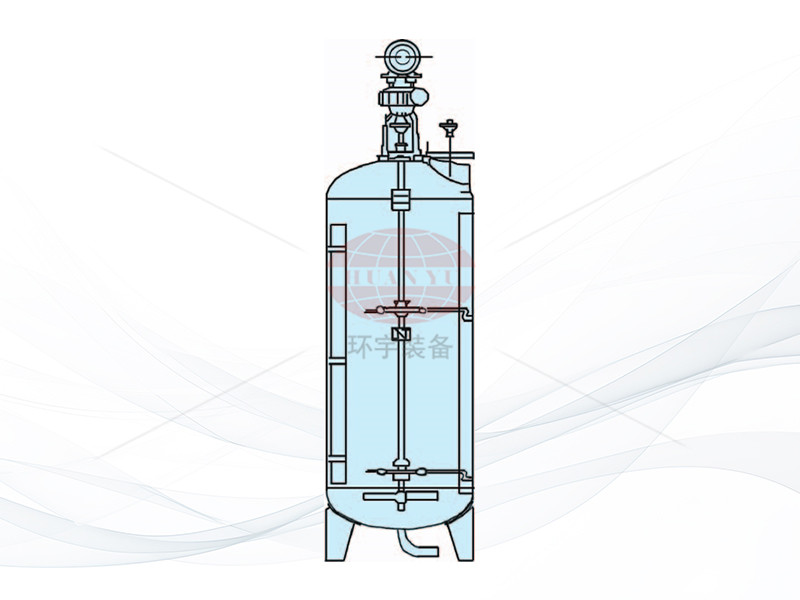

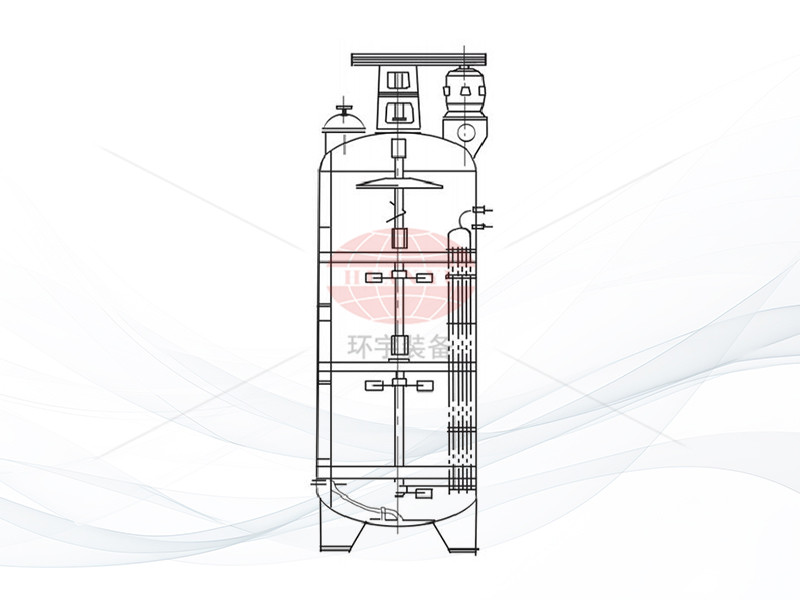

Mixing tank

Quality first, attentive service

<strike id="o6mqs"></strike>

Mixing tank

Quality first, attentive service

The ingredient tank is an auxiliary equipment that provides the base material for the fermentation tank.

In order to obtain a good gas-solid mixture of base materials in the equipment, baffles and agitators are installed inside the tank. The size of the baffles is determined by the diameter and height of the tank, while the agitator uses paddle blades, whose size is determined by the diameter of the tank.

|

|

| Nominal volume(M³) | Mixing shaft speed(r.p.n) | Gearbox model | Y-shaped electric motor | Diameter of angle pulley | Model and quantity of V-belt | Mixing slurry type | |||

| Rotational speed (r.p.n) | Power (KW) | Current (A) 380V | Electric power machine (MM) | Reducer (MM) | |||||

| 0.5 | 80 | A120 | 1430 | 3 | 6.39 | 140 | 155 | B-2 | Paddle |

| 1 | 80 | A120 | 1430 | 3 | 6.39 | 140 | 155 | B-2 | Paddle |

| 2 | 80 | A150 | 1440 | 5.5 | 11.1 | 140 | 155 | B-3 | Paddle |

| 3 | 80 | A150 | 1440 | 5.5 | 11.1 | 140 | 155 | B-3 | Paddle |

| 4 | 80 | A150 | 1440 | 5.5 | 11.1 | 140 | 155 | B-3 | Paddle |

| 5 | 80 | A150 | 1440 | 5.5 | 11.1 | 140 | 155 | B-3 | Paddle |

| 8 | 80 | M10 | 1460 | 11 | 21.8 | 140 | 155 | B-4 | Paddle |

| 10 | 80 | M10 | 1460 | 11 | 21.8 | 140 | 155 | B-4 | Paddle |

| 15 | 80 | M10 | 1460 | 11 | 21.8 | 140 | 155 | B-4 | Paddle |

| 20 | 80 | M10 | 1460 | 11 | 21.8 | 140 | 155 | B-4 | Paddle |

| 25 | 77 | PLW—270 type | 1460 | 13 | 25.6 | 200 | 200 | C-3 | Paddle |

| 30 | 77 | PLW—270 type | 1460 | 13 | 25.6 | 200 | 200 | C-3 | Paddle |